Input Values for Machining

Glossary

| Term | Tag, unit of measure | Explanation |

|---|---|---|

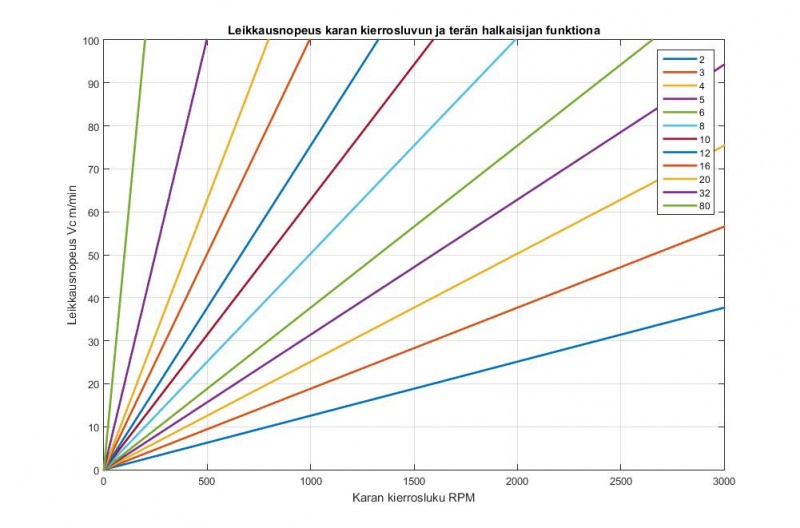

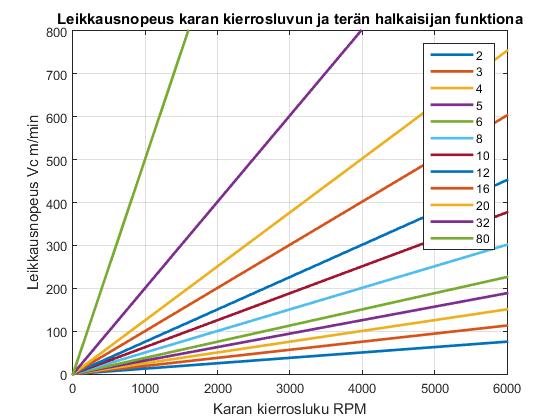

| Speed | RPM (S), rpm | Rotational speed of the rotating tool (in G code S , speed). The rotational speed of the cutter, always on the spindle. In the G code, the spindle speed is commanded with the codeword Snnnnn where nnnnn is the desired speed in RPM. |

| Cutting speed | V c , m / min | The speed at which the cutting blade of the tool cuts into the workpiece. The tool radius and rotational speed together determine the cutting speed. Cutting speed ranges are recommended for different tool and workpiece materials to which the cutting speed of the machining should be adapted. |

| Machining speed | V f (F), mm / min | Tool advance or path speed in the workpiece (in G code F, feed). |

| Tool Number of Teeth | z n , N | Number of cutting blades for the tool. Fixed end mills usually have 2-5 blades, sometimes more. The number of blades for replacement tools can be very large, a dozen or more. Note that the number of pieces in the blade may not be the same as the Number of Teeth. A so-called hedge trimmer typically has several axially overlapping pieces that act as a single tooth depending on the depth of cut. Likewise, there are serrated discs that mill every other tooth from the other edge and vice versa. |

| Tooth feed | f z , mm / tooth | The speed of rotation of the blade, the number of teeth and the speed of the path determine how much the blade advances when one tooth in turn cuts the workpiece. This advance is a tooth-specific feed and at the same time determines the chip thickness. For the blade and the material to be machined, there is typically a desired chip thickness range in which the machining values should be aimed. The feed per tooth, together with the speed and the machining speed, determine the cutting load and thus the power required from the spindle. The cutting load also describes the load on the tool and care must be taken that the load does not exceed the durability of the tool. |

Machining values

| Leikattava materiaali | Työkalun materiaali | Työstöarvot; huomautukset |

|---|---|---|

| Alumiini, puhdas | HSS | Esimerkki |

| Alumiini, puhdas | Karbidi, pinnoittamaton | Esimerkki |

| Rakenneteräs (ST37) | HSS | Vc: 15...30 m/min, fz: 0,05...0,2 mm |

| Rakenneteräs (ST37) | Karbidi, TiAlN | Vc: 100...300 m/min, fz: 0,05...0,3 mm |

| Rakenneteräs (ST56) | HSS | Esimerkki |

| Rakenneteräs (ST56) | Karbidi, TiAlN | Esimerkki |

| Ruostumaton teräs (A2, AISI 306) | HSS | Esimerkki |

| Ruostumaton teräs (A2, AISI 306) | Karbidi | Esimerkki |

| Haponkestävä teräs (A4, AISI 316) | HSS | Esimerkki |

| Haponkestävä teräs (A4, AISI 316) | Karbidi | Esimerkki |

| Esimerkki | Esimerkki | Esimerkki |

| Esimerkki | Esimerkki | Esimerkki |

| Esimerkki | Esimerkki | Esimerkki |