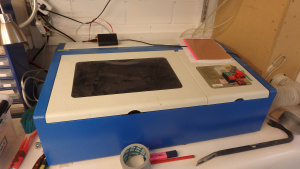

Optinen kaiverrin

History

Status: Donated to Hacklab Jyväskylä in 03/2018

General Information

The optical engraver is connected to a Raspberry PI 3 Model B with Raspbian Jessie running version 3.256.0 of LaserWeb3.

- multicast address: laserweb.local

- IPv4: 192.168.110.176 (not guaranteed to be the same)

- LaserWeb is listening on port 8000

- LaserWeb: try connecting with /dev/tty/ACM0 + 115200

Control panel buttons

BEAM

- must be enabled before engraving or cutting

- dry run the process using 0 position

Manual test, safety switch

- test the beam manually (for material tests etc.)

0-10 dial

- set maximum reference power of the beam

Steps to engrave/cut an SVG:

Please note that currently the X axis of the engraver is inverted. This results in mirrored engravings. Flip the SVG horizontally to fix this.

Preparig the Machine

- Make sure the power is turned on both in the extension cords and in the machine itself

- Install the workpiece and close the lid

- Turn the laser on (green button, check that the red led turns on)

- Turn on the lights (flip the small metallic switch)

- Check that the laser power is set at an appropriate level

Engraving the SVG

Note that only SVG paths can be engraved. Convert text and other objects into paths (e.g. with InkScape).

- Browse to http://192.168.110.165:8000 or http://laserweb.local:8000

- Click the Open button and select an SVG image or drag-and-drop it

- Configure the feedrate, number of passes and depth of each pass

- Click the Generate G-Code button

- Click the Process button to load the G-Code

- Click the run gcode (Play) button to run the G-Code

- After the machine is idle, click the home laser button to return the laser home

Engraving pre made gcode

Upload gcode as it was any other source file (such as svg, graphics, etc.). Open gcode file in CAM, then "generate gcode" - it just replicates the code as it is!

The machine operates with these codes:

- S0.0 Turn beam off (use 0% of beam power)

- S1.0 Turn beam on (100%)

Installing the Workpiece

- If possible, use the clamps. The laser focus seems to be good at the depth of the clamp.

- The maximum height of an object that fits the clamp is roughly 80mm.

- If engraving larger pieces, make sure that they stay still and don't move. Some duct tape or a few drops of superglue should hold them still.

Observations on Cutting Depths

6mm acrylic

| Feedrate | Laser Current | Passes | Cut depth observations |

|---|---|---|---|

| 20mm | 5mA | 10 | Barely a scratch, might work for engravings |

| 20mm | 10mA | 5 | About the same as 5mW x 10 |

| 20mm | 15mA | 5 | Roughly half a millimeter |

| 20mm | 20mA | 5 | Roughly half a millimeter |

| 20mm | 20mA | 30 | Around 2-3mm, acrylic started to melt |

| 40mm | 20mA | 30 | Around 2-3mm, clean cut |

4mm acrylic

40mm feedrate with full power (20mA) took about 60 passes to cut through 4mm acrylic.

Stamp rubber

Using full power burns the material black (might not happen during the first pass), which prevents beam engraving the material. Don't use maximum power, reduce if any charring appears. Make multiple passes. Use about 40% power in the dial, see if any charring happens. You can probably lift the power a bit, if the work path does not contain large continuous areas to be removed. Observe.

Debugging

If the engraver doesn't seem to be connected to LaserWeb, try reconnecting the USB cable to the engraver and then reload the web page.

Further reading and training

10 Tips&Tricks: http://www.instructables.com/id/10-Tips-and-Tricks-for-Laser-Engraving-and-Cutting/

Cleaning laser engraved wood: http://www.instructables.com/id/Cleaning-Laser-Engraved-Wood-20/

Playlist of laserweb videos: https://www.youtube.com/playlist?list=PL1JTb6-HQgOyc1eM6eX4v0tdSYpXFLYNT

Laserweb support community: https://plus.google.com/communities/115879488566665599508